Here’s a professional datasheet-style introduction for VIBRO METER IOC16T 200-565-101-013 with detailed parameters, English description, and a recommendation table for similar products:

📘 VIBRO METER IOC16T 200-565-101-013 Datasheet

🔹 Product Overview

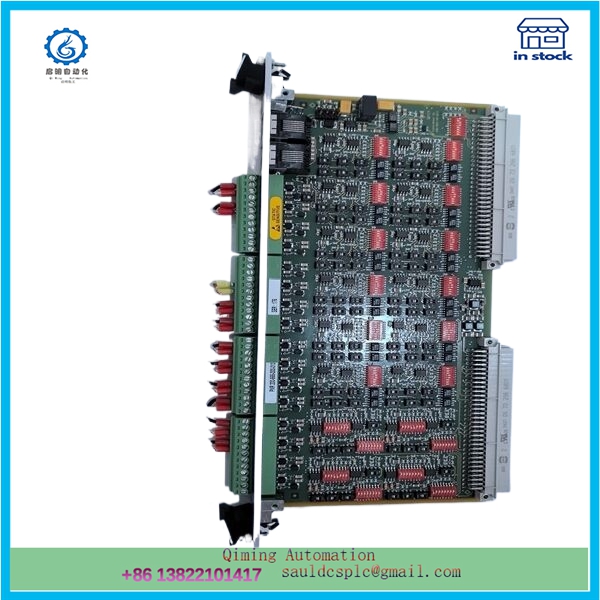

The VIBRO METER IOC16T 200-565-101-013 is a high-precision industrial input/output controller module specifically designed for vibration monitoring and condition-based maintenance systems. It is widely used in industries such as power generation, petrochemical, and heavy machinery, providing reliable measurement and control of critical machinery parameters.

Engineered for robust performance in harsh industrial environments, this module ensures accurate data acquisition, efficient processing, and seamless integration with larger monitoring networks. Its design prioritizes signal integrity, operational stability, and long-term reliability, making it ideal for applications requiring continuous monitoring of rotating machinery, turbines, and other high-speed equipment.

🔹 Key Features

- ⚙️ High Accuracy – Delivers precise analog and digital signal measurement.

- 🔌 Seamless Integration – Compatible with VIBRO METER and other OEM monitoring systems.

- 🛡️ Robust Design – Resistant to temperature extremes, vibration, and electromagnetic interference.

- 🛠️ Maintenance-Friendly – Modular construction allows easy replacement and upgrades.

- 📡 Reliable Data Communication – Supports continuous signal transmission for real-time monitoring.

- 🌡️ Wide Operating Range – Suitable for environments from -20°C to +70°C.

🔹 Technical Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | VIBRO METER |

| Model Number | IOC16T 200-565-101-013 |

| Product Type | I/O Controller Module |

| Input Voltage | 24 VDC nominal |

| Signal Types | Analog, Digital |

| Channel Count | 16 Inputs / 16 Outputs |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% – 95% non-condensing |

| Mounting | Rack-mounted |

| Weight | Approx. 1.0 kg |

| Dimensions | Standard 3U rack module |

| Isolation | Electrical & optical isolation |

| Certification | CE, UL approved |

🔹 Applications

- 🏭 Rotating Machinery Monitoring in power plants

- ⚡ Turbine Condition Assessment in energy generation

- 🛢️ Petrochemical & Refining Plant equipment diagnostics

- 🏗️ Industrial Manufacturing for predictive maintenance

- 🚉 Heavy Machinery vibration monitoring

🔹 Installation & Maintenance

The IOC16T module is designed for rack-mounted installation. Correct alignment and secure connection to the backplane are essential for optimal performance.

Maintenance Recommendations:

- Inspect module slots and connectors regularly.

- Clean dust and ensure proper airflow inside the control rack.

- Replace only with certified VIBRO METER modules.

- Maintain system firmware updates for compatibility and improved performance.

🔹 Advantages

✅ High-precision signal acquisition

✅ Compatible with legacy and modern VIBRO METER systems

✅ Low maintenance for continuous operation

✅ Strong environmental resilience

✅ Modular for easy upgrades and replacement

🔹 Useful Resource

For further VIBRO METER system components and modules, visit:

👉 Stardcsplc Industrial Automation

🔹 Recommended Similar Products

| Model | Description | Application | More Info |

|---|---|---|---|

| VIBRO METER IOC16 200-565-101-012 | I/O Controller Module | Machinery monitoring | View Here |

| VIBRO METER IOC32T 200-565-102-015 | High-channel I/O Module | Turbine diagnostics | View Here |

| VIBRO METER IOL8T 200-565-103-010 | Analog/Digital I/O Module | Rotating equipment | View Here |

| VIBRO METER IOC16P 200-565-104-011 | Processor Module | Industrial monitoring | View Here |

| VIBRO METER IOC16S 200-565-105-012 | Signal Conditioning Module | Predictive maintenance | View Here |

✦ The VIBRO METER IOC16T 200-565-101-013 continues to provide precision, durability, and seamless integration, making it an essential component for industrial condition monitoring and predictive maintenance systems.

I can also create a visual infographic-style datasheet for this module with icons for features, technical specs, and applications. This would make it more visually appealing for presentations or catalogs. Do you want me to do that?