Here’s a detailed draft for the VIBRO METER 204-040-100-012 Rack datasheet-style introduction in English, with icons, parameters, and a recommendation table:

📘 VIBRO METER 204-040-100-012 Rack – Product Datasheet

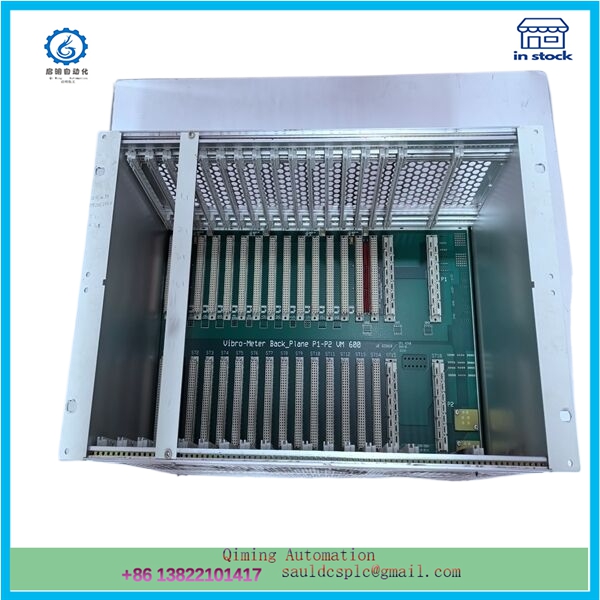

The VIBRO METER 204-040-100-012 Rack is a high-reliability monitoring platform engineered for advanced vibration and condition monitoring applications in demanding industrial environments. Designed to integrate seamlessly with vibration sensors, signal conditioners, and protection modules, this rack provides the essential backbone for turbine, compressor, and rotating machinery supervision. Its robust design ensures operational continuity, precision, and safety for critical assets.

🔧 Key Features

- Modular Design: Supports multiple plug-in monitoring modules for flexible configurations.

- Signal Integrity: Optimized for low-noise, high-fidelity transmission of vibration and dynamic signals.

- Scalability: Accommodates future expansion with additional slots.

- Rugged Construction: Built with industrial-grade materials for harsh environments.

- System Integration: Compatible with supervisory control systems for seamless plant monitoring.

- Fail-Safe Operation: Designed with redundant architecture to safeguard data and ensure continuous monitoring.

📊 Technical Specifications

| Parameter | Description |

|---|---|

| Model | VIBRO METER 204-040-100-012 |

| Type | Monitoring Rack |

| Input Compatibility | Vibration sensors, transducers, accelerometers |

| Power Supply | 24 VDC or AC (depending on configuration) |

| Number of Slots | 12 (standard), modular expansion available |

| Material | Heavy-duty aluminum alloy |

| Mounting | Rack-mounted, 19-inch standard frame |

| Operating Temperature | -20°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Weight | Approx. 7.5 kg (depending on module configuration) |

| Cooling | Passive ventilation, fan-assisted optional |

| Connectivity | Rear panel connectors, BNC, screw terminals |

| Compliance | IEC / EN standards for vibration monitoring systems |

⚙️ Applications

- Turbine vibration monitoring in power generation plants

- Compressor condition monitoring in petrochemical industries

- Critical rotating equipment in aerospace test benches

- Predictive maintenance programs for heavy industrial assets

🛠️ Installation & Maintenance

- Installation: Mount the rack in a 19-inch cabinet with secure grounding to ensure signal stability. Connect input modules to vibration sensors through shielded cables.

- Maintenance: Perform periodic checks on module seating, rear connectors, and ventilation. Replace modules using the hot-swap procedure without powering down the system. Dust cleaning and connector inspection are recommended every 12 months.

- Calibration: Ensure module calibration according to manufacturer guidelines at intervals of 2 years to maintain measurement accuracy.

🔗 Useful Links

📌 Recommended Similar Products

| Model | Description | Link |

|---|---|---|

| VIBRO METER 204-040-100-013 | Extended monitoring rack with higher slot capacity | View |

| VIBRO METER 200-570-000-011 | Compact vibration monitoring unit | View |

| VIBRO METER 204-030-000-010 | Modular rack with integrated power supply | View |

| VIBRO METER 200-502-000-005 | Signal conditioner rack for multi-sensor systems | View |

| VIBRO METER 204-050-000-012 | Advanced rack system with redundant architecture | View |

Would you like me to also create a Chinese version of this datasheet (带图标,参数表格,推荐型号),so you have both English and Chinese product pages for different markets?