📘 VIBRO METER CMC16 200-530-111-013 Datasheet

🔹 Product Overview

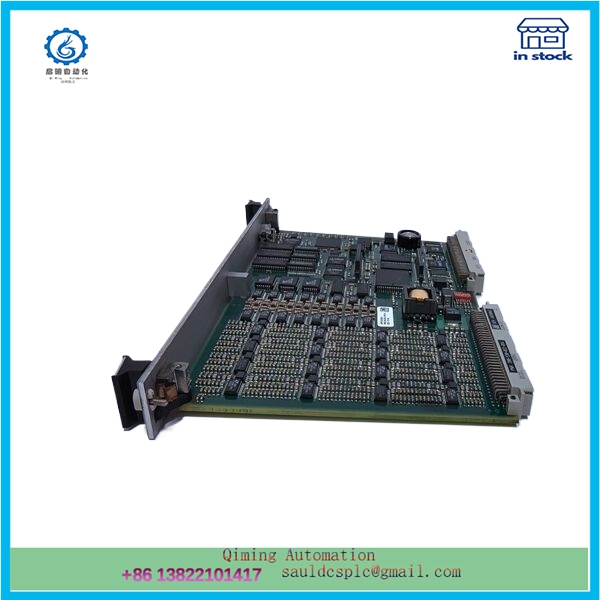

The VIBRO METER CMC16 200-530-111-013 is an advanced condition monitoring and control module designed for critical rotating machinery applications. Developed with high-performance electronics, this module provides reliable data acquisition, processing, and communication capabilities. It is used in industries such as power generation, oil & gas, marine propulsion, and heavy manufacturing, where vibration monitoring and machinery protection are essential for safety and operational continuity.

The CMC16 is engineered to integrate seamlessly into complex monitoring systems, offering robust protection, diagnostic capabilities, and scalable architecture for plant-wide machinery management.

⚙️ Technical Parameters

| Parameter | Specification |

|---|---|

| Model Number | CMC16 200-530-111-013 |

| Manufacturer | Vibro-Meter |

| Function | Condition monitoring and control module |

| Input Channels | 16 dynamic channels (configurable for vibration, pressure, speed, or other sensors) |

| Signal Types | Voltage, current, dynamic vibration sensors (IEPE, velocity, proximity probes) |

| Frequency Range | Up to 20 kHz depending on sensor configuration |

| Processing | Real-time signal conditioning, filtering, and FFT analysis |

| Outputs | Digital and analog outputs for alarm, trip, and control functions |

| Interfaces | Ethernet TCP/IP, Modbus, and proprietary monitoring protocols |

| Power Supply | 24 VDC (typical), redundant supply option |

| Operating Temperature | -20 °C to +65 °C |

| Mounting | Rack-based modular installation |

| Compliance | CE, EMC, and industrial safety standards |

| Part Number | 200-530-111-013 |

🛠️ Key Features

- Multi-channel capability: Supports up to 16 configurable inputs for flexible system integration.

- High-speed processing: Provides real-time analysis of vibration and dynamic signals for early fault detection.

- Advanced diagnostics: Includes trending, alarm management, and root cause analysis tools.

- Robust protection: Built-in trip relays ensure machinery shutdown under unsafe conditions.

- Scalable architecture: Rack-based modular design allows system expansion without downtime.

- Flexible communication: Compatible with modern industrial networks and supervisory control systems.

- Rugged design: Engineered for harsh environments with extended temperature tolerance and high EMI immunity.

🔧 Installation & Maintenance

- Mounting: Designed for installation within a rack system. Ensure proper ventilation and vibration isolation of the cabinet.

- Wiring: Shielded cables recommended for vibration sensor connections to minimize interference.

- Commissioning: Configure channel allocation via system software before connecting machinery.

- Calibration: Annual verification of sensor signals and system alarms is advised.

- Maintenance: Minimal, with only periodic inspections and firmware updates required for long-term reliability.

📡 Applications

- Turbomachinery – Gas turbines, steam turbines, and compressors.

- Industrial Pumps & Fans – Continuous monitoring to prevent costly downtime.

- Marine Engines – Critical monitoring for propulsion systems.

- Power Plants – Condition-based maintenance for generators and auxiliary equipment.

- Oil & Gas Facilities – Reliable vibration monitoring in hazardous areas.

🔗 Related Links

- For more industrial automation and monitoring modules, visit: https://www.stardcsplc.com/

- Explore advanced vibration monitoring systems here: https://www.stardcsplc.com/

📑 Recommended Similar Products

| Model | Description | Manufacturer | Link |

|---|---|---|---|

| VIBRO METER CMC10 200-520-111-005 | Compact monitoring module for smaller systems | Vibro-Meter | View |

| VIBRO METER VM600 200-510-000-040 | Rack-based monitoring platform for turbomachinery | Vibro-Meter | View |

| BENTLY NEVADA 3500/22M | Machinery protection system with flexible communication options | Bently Nevada | View |

| EMERSON CSI 6500 | Online machinery health monitoring system | Emerson | View |

| PRÜFTECHNIK VIBXPERT II | Portable vibration data collector and analyzer | Prüftechnik | View |

Would you like me to also create a Chinese version datasheet for this product (to match your earlier style requests), or should we keep this series fully in English?

Here’s a full datasheet-style introduction for VIBRO METER CMC16 200-530-111-013, written in English with technical detail, structured parameters, and product recommendations at the end.

📘 VIBRO METER CMC16 200-530-111-013 Datasheet

🔹 Product Overview

The VIBRO METER CMC16 200-530-111-013 is an advanced condition monitoring and control module designed for critical rotating machinery applications. Developed with high-performance electronics, this module provides reliable data acquisition, processing, and communication capabilities. It is used in industries such as power generation, oil & gas, marine propulsion, and heavy manufacturing, where vibration monitoring and machinery protection are essential for safety and operational continuity.

The CMC16 is engineered to integrate seamlessly into complex monitoring systems, offering robust protection, diagnostic capabilities, and scalable architecture for plant-wide machinery management.

⚙️ Technical Parameters

| Parameter | Specification |

|---|---|

| Model Number | CMC16 200-530-111-013 |

| Manufacturer | Vibro-Meter |

| Function | Condition monitoring and control module |

| Input Channels | 16 dynamic channels (configurable for vibration, pressure, speed, or other sensors) |

| Signal Types | Voltage, current, dynamic vibration sensors (IEPE, velocity, proximity probes) |

| Frequency Range | Up to 20 kHz depending on sensor configuration |

| Processing | Real-time signal conditioning, filtering, and FFT analysis |

| Outputs | Digital and analog outputs for alarm, trip, and control functions |

| Interfaces | Ethernet TCP/IP, Modbus, and proprietary monitoring protocols |

| Power Supply | 24 VDC (typical), redundant supply option |

| Operating Temperature | -20 °C to +65 °C |

| Mounting | Rack-based modular installation |

| Compliance | CE, EMC, and industrial safety standards |

| Part Number | 200-530-111-013 |

🛠️ Key Features

- Multi-channel capability: Supports up to 16 configurable inputs for flexible system integration.

- High-speed processing: Provides real-time analysis of vibration and dynamic signals for early fault detection.

- Advanced diagnostics: Includes trending, alarm management, and root cause analysis tools.

- Robust protection: Built-in trip relays ensure machinery shutdown under unsafe conditions.

- Scalable architecture: Rack-based modular design allows system expansion without downtime.

- Flexible communication: Compatible with modern industrial networks and supervisory control systems.

- Rugged design: Engineered for harsh environments with extended temperature tolerance and high EMI immunity.

🔧 Installation & Maintenance

- Mounting: Designed for installation within a rack system. Ensure proper ventilation and vibration isolation of the cabinet.

- Wiring: Shielded cables recommended for vibration sensor connections to minimize interference.

- Commissioning: Configure channel allocation via system software before connecting machinery.

- Calibration: Annual verification of sensor signals and system alarms is advised.

- Maintenance: Minimal, with only periodic inspections and firmware updates required for long-term reliability.

📡 Applications

- Turbomachinery – Gas turbines, steam turbines, and compressors.

- Industrial Pumps & Fans – Continuous monitoring to prevent costly downtime.

- Marine Engines – Critical monitoring for propulsion systems.

- Power Plants – Condition-based maintenance for generators and auxiliary equipment.

- Oil & Gas Facilities – Reliable vibration monitoring in hazardous areas.

🔗 Related Links

- For more industrial automation and monitoring modules, visit: https://www.stardcsplc.com/

- Explore advanced vibration monitoring systems here: https://www.stardcsplc.com/

📑 Recommended Similar Products

| Model | Description | Manufacturer | Link |

|---|---|---|---|

| VIBRO METER CMC10 200-520-111-005 | Compact monitoring module for smaller systems | Vibro-Meter | View |

| VIBRO METER VM600 200-510-000-040 | Rack-based monitoring platform for turbomachinery | Vibro-Meter | View |

| BENTLY NEVADA 3500/22M | Machinery protection system with flexible communication options | Bently Nevada | View |

| EMERSON CSI 6500 | Online machinery health monitoring system | Emerson | View |

| PRÜFTECHNIK VIBXPERT II | Portable vibration data collector and analyzer | Prüftechnik | View |

Would you like me to also create a Chinese version datasheet for this product (to match your earlier style requests), or should we keep this series fully in English?